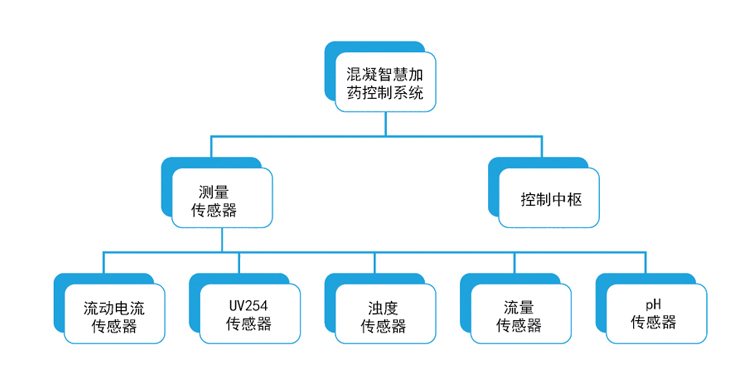

BT-9000L coagulation intelligent dosing control system is composed of flowing current, organic matter (UV254), turbidity and pH modules, and the control scheme is obtained through relevant calculations based on the data of different modules.

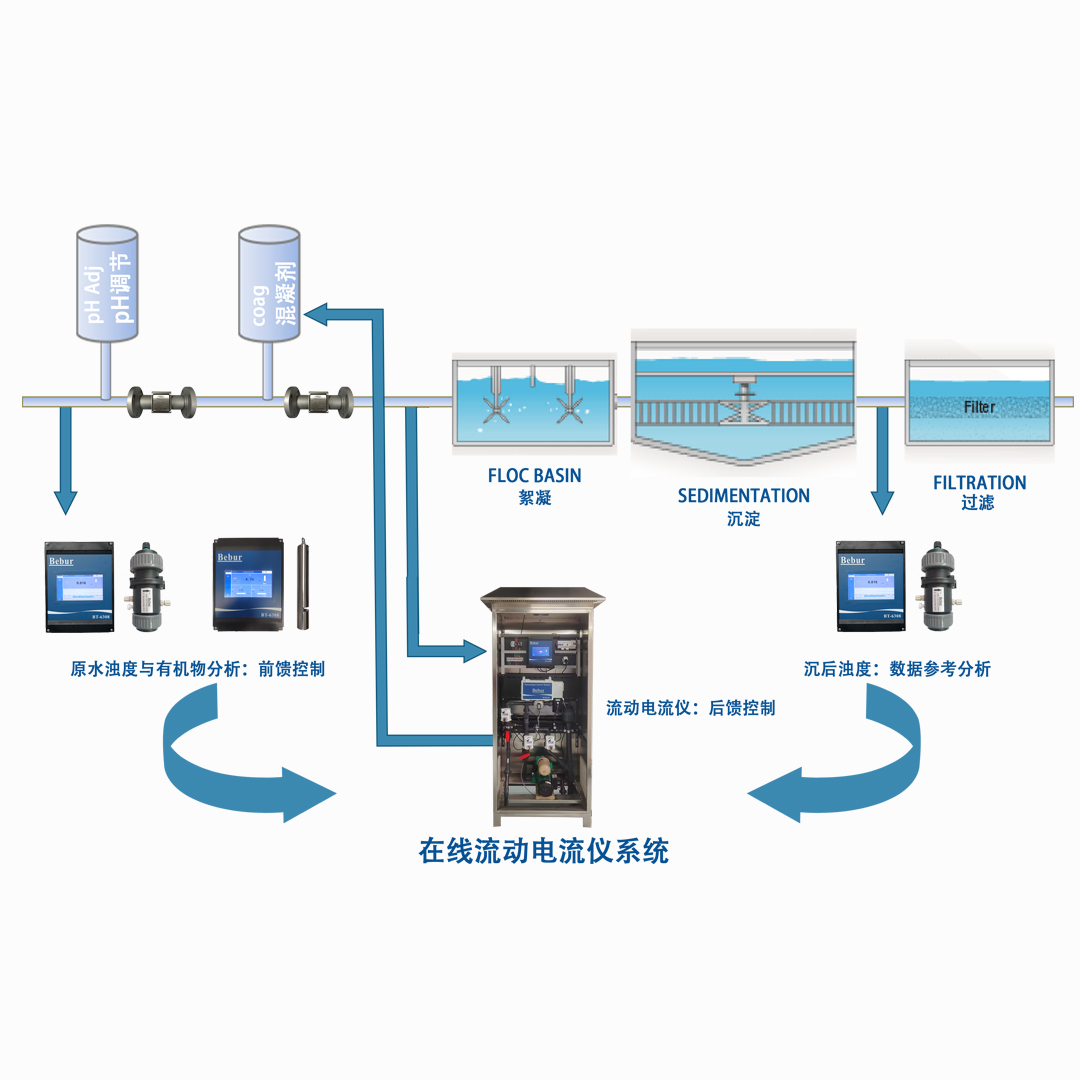

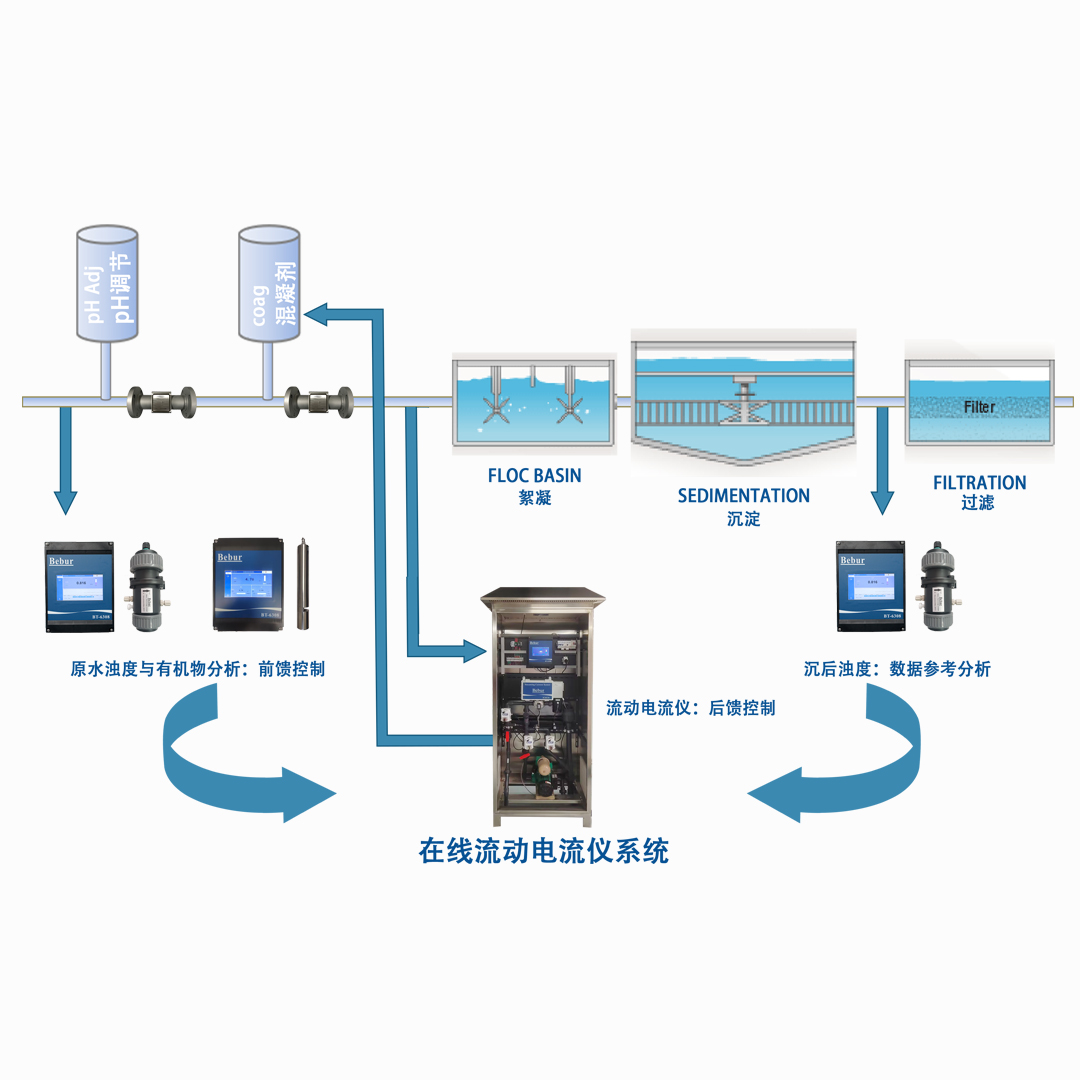

BT-9000L coagulation intelligent dosing control system is composed of flowing current, organic matter (UV254), turbidity and pH modules, and the control scheme is obtained through relevant calculations based on the data of different modules. The system has several built-in control loops: turbidity and organic matter feed-forward control loops; Flowing current SCD feed-backward control forms a closed-loop control circuit. Different control loops are selected according to the water quality parameters of different modules to control the coagulant dosing. The non-participating loop is used to compare the output results of the participating loop for correction and validation.

BT-9000L coagulation intelligent dosing control system is a modular system with simple operation and lower cost compared with multi-parameter AI system, which is suitable for all users. It can receive signals from existing sensor and can receive signals from on-site PLC/SCADA, thus realizing multiple modes - manual, individual flow ratio, parameter control, with dosage validated.

BT-9000L coagulation intelligent dosing control system fits the coagulation mechanism, and has a variety of control logics to cooperate with each other and validate each other. The system has the features such as accuracy and stability, safety and efficiency, clear logics, low maintenance, less investment and short commissioning cycle and the provision of high efficiency PID control module, and it can be combined with the automatic control system of the water plant or run independently, with a more flexible work mode.

The coagulation intelligent dosing control system is composed of dosing unit, detection unit and control unit, all of which are integrated on a platform.

※ Optimize water quality and save manpower

※ Realize the automatic control of coagulant dosing based on different control loops

※ The dosage of coagulant can be reduced under the same raw water conditions

※ More stable processes, fewer abnormal shutdowns

※ A control system with higher independence and cost performance ratio

※ Complex intervention in coagulation control

BT-9000L coagulation intelligent dosing control system has a wide range of adaptability and flexibility, allowing different single parameter to be controlled at any time, and the active control parameters can be changed on the system by an authorized personnel. The parameters that are not in active control can be used to validate the control parameters and alarm.

The piston of the streaming current detector reciprocates up and down inside the ring electrode. When the water sample added with coagulant passes through the flow current meter sensor, the water in the electrode ring space also makes corresponding movement, colloidal particles double electric layer is disturbed, the water will carry the counter-ions in the colloid diffusion layer to move together, thus forming the flow of current, which is collected by the electrodes at both ends, amplified by a signal amplifier and rectified into a DC signal output. When the concentration of colloidal particles in water changes, the detection value collected by the flow current meter will also change accordingly. In this way, it can provide a real-time and reliable detection basis for the coagulation effect of raw water.

The flow current meter can be equipped with self-cleaning function, and the flow current sensor can be cleaned on a regular basis according to the set cleaning time, which can improve the adaptability of the system to poor water quality conditions.

The optimal dosage of coagulant can be determined by detecting SCV response value of raw water with flow current meter, in order to reduce dosage consumption and cost on the basis of ensuring and improving water quality, and then improve economic and social benefits of the enterprise.

pH value is an important parameter in coagulation control. If the pH value exceeds the pre-set range or an independent PID control loop is required to prioritize controlling the pH value of the raw water, it is required to measure the pH value and set the pH value to give an alarm reminder.

In case of lower turbidity, using a signal from UVA for feed-forward control can achieve the removal of organic matter and THM.

In case of higher water turbidity value or lower UVA value, the UV254 sensor reaction becomes slow and organic matter is no longer measured. At this point, another conventional control parameter in the control system will function in control.

The flow rate can be adjusted to increase or decrease the coagulant dosing proportion.

Note: If the user site already has the analytical instruments for analyzing residual chlorine, turbidity and pH value, it is also possible to connect these parameters directly to the coagulation intelligent dosing control system for centralized display and control.

When purchasing, please inform the field or industry of use and the characteristics of the measuring medium in order to provide appropriate technical service guidance.

The standard supplies of Bebur BT-9000L coagulation intelligent dosing control system include streaming current detector, pH analyzer, turbidity analyzer, metering pump, coagulation control system, electromagnetic flowmeter, control valve, damper, etc.