The Bebur SCM520 Streaming Current Monitor is a device that detects the charge (similar to Zeta potential) of ions and colloids in water based on the principle of flow current, and is used for automatically regulating and controlling the dosage of coagulants. Through real-time monitoring, intelligent control and precise dosing, Achieve stable water quality compliance, save chemicals, reduce costs and increase efficiency, and improve the operational efficiency of water plants, etc.

The Bebur SCM520 Streaming Current Monitor is a device that detects the charge (similar to Zeta potential) of ions and colloids in water based on the principle of flow current, and is used for automatically regulating and controlling the dosage of coagulants. Through real-time monitoring, intelligent control and precise dosing, Achieve stable water quality compliance, save chemicals, reduce costs and increase efficiency, and improve the operational efficiency of water plants, etc.

▪The Bebur SCM520 Streaming Current Monitor is applied in processes that require the addition of coagulants, such as municipal/industrial water treatment, sludge sedimentation and dewatering/filtration, papermaking, and pretreatment of reverse osmosis systems.

▪It can simultaneously detect parameters that have an impact on the coagulation process, such as pH, turbidity, UV254 organic matter, etc

▪Excellent sensor signals, health diagnosis and pH compensation functions

▪Optimize the dosage of coagulants and reduce the cost of chemical dosing

▪Maintain the stability of the effluent quality and reduce the frequency of backwashing of the filter

▪Reduce contaminants on the filter membrane and extend the operating time of the filter

▪A variety of excellent optional features - over-protection, delayed start, slow acceleration at set values, etc

▪The sturdy and durable structure design that users can maintain by themselves reduces the user's usage cost

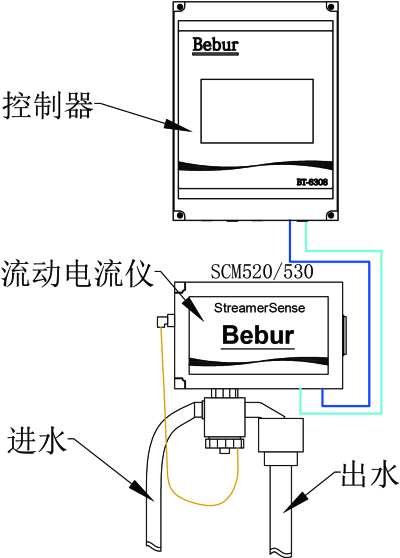

The water sample flows into the sampling tank. When the piston moves upward, the water sample is carried into the hole. When the piston moves downward, the sample water is discharged from the hole. The particulate matter in the water temporarily adheres to the surface of the piston and the cylinder. When the water is pushed back forward by the piston, the positive and negative electrons around these particulate matter move downward to the electrodes. The detected signal is amplified and eventually converted into the SCV display value. The current generated by this kind of current movement is called "stream current".

Power supply:100-240VAC/0.75A

Language:Free to select multiple languages

Input:Standard 4-way sensor signal input,which is expandable to 16-way input

Output:Standard RS485 signal output and relay output,4-20mA signal output is optional

Shell:Flame-retardant ABS =Protection Grade:IP65

Size:230x09x103

Weight:2kg

Sample Flow | 1-19L/min |

Measurement | Streaming current |

Measuring Range | -1000~1000 |

Sample Cell | External receiver,high flow |

Piston | Quickly replaceable |

Water Sample Inlet | 3/4"(19mm)OD |

Water Sample Outlet | 3/4"(19mm)OD |

Materials of Contact | PVDF,POMor PVDF,PVCor PE,EPDM,stainless steel |

Wiring Connection | Shielded wire with four conductors |

Self-Diagnosis | Motor Speed |

Enclosure | PC |

Power Requirements | 220VAC,50HZ |

Working Temperature | 0-50℃ |

Heat Dissipation | Yes |

Overall Dimension | 310mm(W),388mm(H),165mm(D) |

Weight | 5KG |

OptionalAccessories | |

Self-cleaning | Automatic sensor cleaning |

Other measurement | pHmeasurement |