The Bebur BT-525 Fixed Gas Detection System adopts a pump suction sampling and measurement instrument system, which is used to monitor and measure toxic gases in the environment or containers.

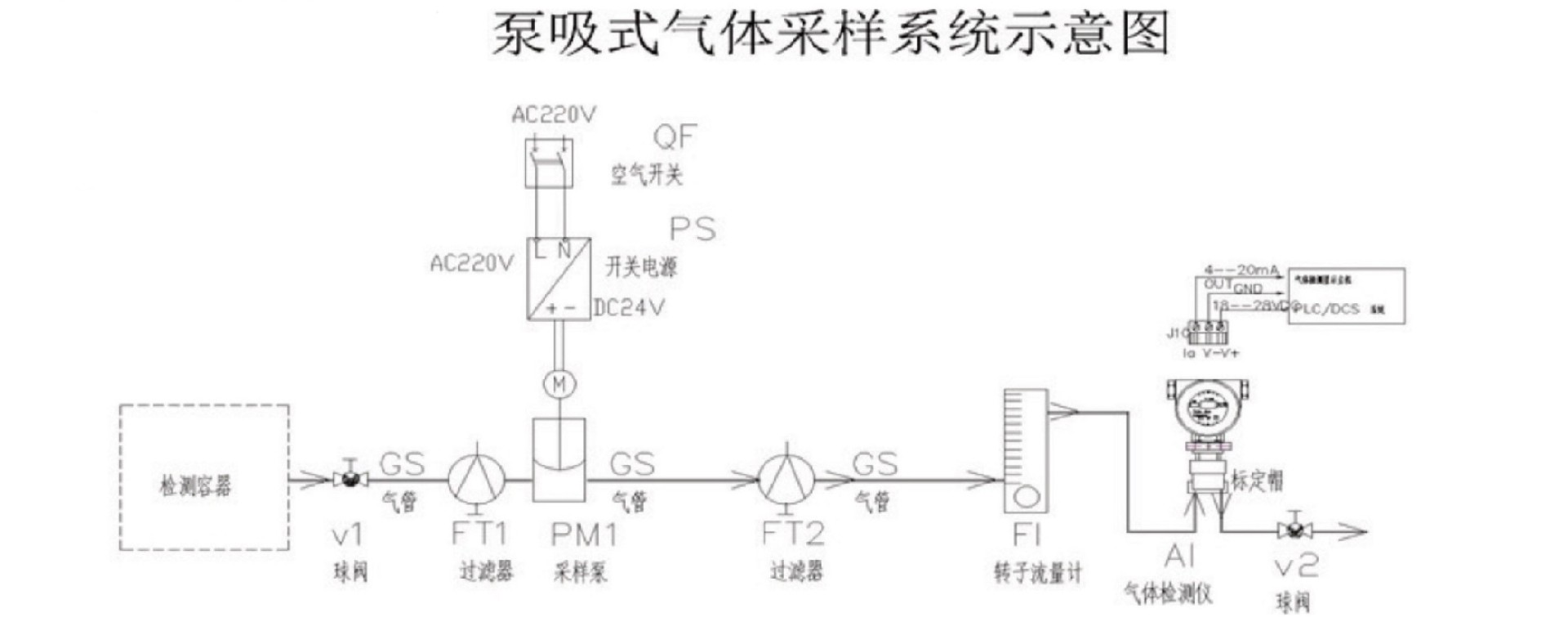

The Bebur BT-525 Fixed Gas Detection System adopts a pump suction sampling and measurement instrument system, which is used to monitor and measure toxic gases in the environment or containers.The field measuring instrument shall be with the function of level-2 alarm display, providing different usage requirements for users. The instrument also transmits the detected gas concentration value to the Central Control Room or monitoring instrument via 4-20mA or RS485 signal mode for remote manager to carry out monitoring work. The detection system can be operated in an environment where the slight negative pressure range does not exceed-40Kpa or the positive pressure does not exceed 80Kpa.

Industries such as water treatment, sewage treatment, food, chemical industry and metallurgy.

The measured gas is transported from the gas tank or pipeline in the field to the measurement inlet of the measuring instrument by using the gas vacuum sampling pump via the ball valve switch, filter and rotor flow meter. The instrument converts the detected gas concentration value into the corresponding value and displays it on the LCD screen. The circular display panel of the alarm instrument is equipped with upper and lower rows of alarm lights, which correspond to low and high values, respectively. When the gas concentration reaches a low reporting value, the alarm light in the lower row will flash, reminding the on-site personnel to note the environmental safety and take relevant safety measures according to the conditions. When the gas concentration reaches a high alarm value, the alarm light in the upper row will flash, warning the relevant personnel to evacuate the site and take relevant protective measures.

Sampling: Constant measurement by pumping

Calibration: IR remote control operation, calibration

Sensor: Electrochemistry

Reaction time: T90<60s<>

Display: Backlight four-bit LCD

Repeatability: ≤±2%

Ambient humidity: 0-95%RH, no condensed water

Instrument protection level: IP66

Power: Instrument box - 220VAC, probe and sampling pump - 24VDC

Measuring instrument: Three-wire system 24VDC

Max. sampling negative pressure: ≤-40KPa

Max. sampling positive pressure: ≤ 80KPa

Box material: Carbon steel sprayed with plastic

Weight: 25kg

Mounting: Wall-mounted

Dimensions: H * W * T 600 * 500 * 260 (mm)

Name | Chemical formula | Standard range | Highest range |

Ammonia | NH3 | 0-100PPM | 0-5000PPM |

Carbon monoxide | CO | 0-200PPM | 0-1000PPM |

Sulfur dioxide | SO2 | 0-100PPM | 0-40000PPM |

Ozone | O3 | 0-5/50PPM | 0-30000PPM |

Ethylene | C2H4 | 0-100PPM | 0-1500PPM |

Ethylene oxide | ETO | 0-100PPM | 0-5000PPM |

Chlorine | CL2 | 0-20PPM | 0-5000PPM |

Hydrogen peroxide | H2O2 | 0-500PPM | 0-2000PPM |

Hydrogen sulfide | H2S | 0-100PPM | 0-5000PPM |

Hydrogen chloride | HCL | 0-100PPM | 0-1000PPM |