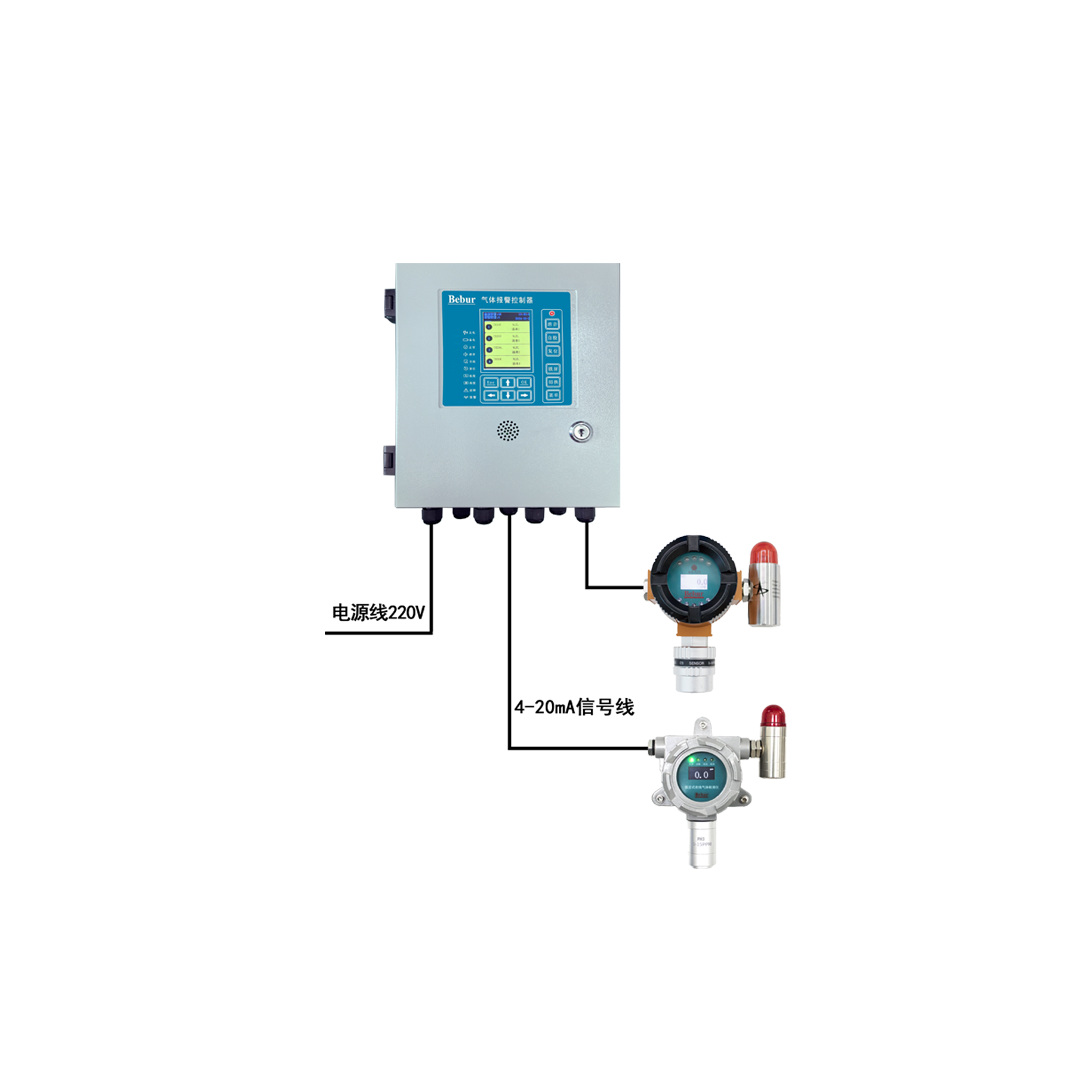

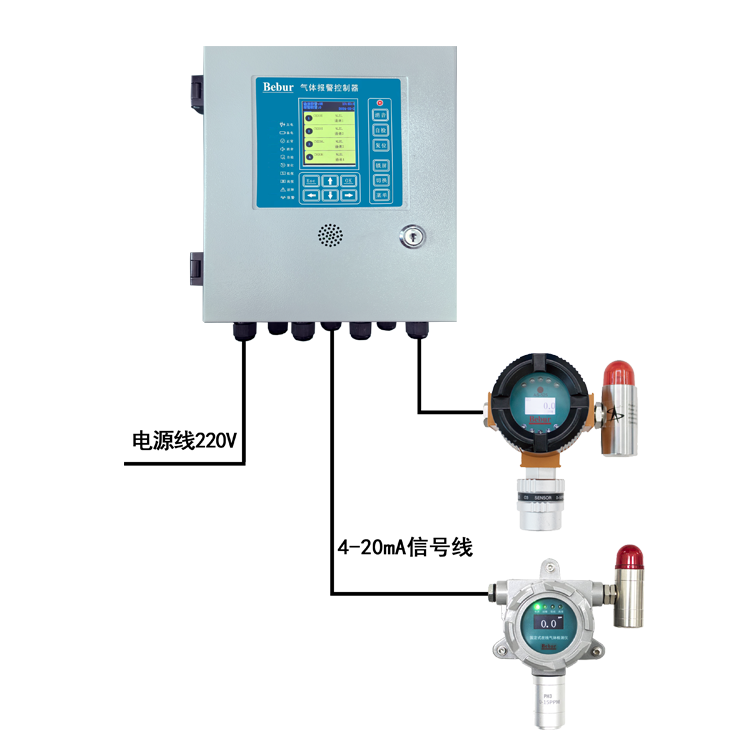

The Bebur AT-2000 Gas Alarm Detection System is composed of gas controller and various combustible and toxic gas detectors. The gas controller can be connected to the monitoring center computer via the cable twisted pairs (485 signal), and the field concentration can be queried in different places via the monitoring software (with the computer networked) of the company, thus forming a multi-level monitoring network of remote monitoring, local monitoring and field monitoring, which greatly improves the timeliness and accuracy of monitoring.

The Bebur AT-2000 Gas Alarm Detection System is composed of gas controller and various combustible and toxic gas detectors. The gas controller can be connected to the monitoring center computer via the cable twisted pairs (485 signal), and the field concentration can be queried in different places via the monitoring software (with the computer networked) of the company, thus forming a multi-level monitoring network of remote monitoring, local monitoring and field monitoring, which greatly improves the timeliness and accuracy of monitoring.

The gas controller shall be wall-mounted, and each channel corresponds to a gas detector. With the gas detector, the data processing unit in the controller processes the data uploaded by the gas detector, and completes the data display, signal output and data recording.

Industries such as water treatment, sewage treatment, food, chemical industry and metallurgy; With stable product performance and low routine maintenance.

The gas controller shall be a 2 .8'' TFT colorful screen with display of Chinese graphics , and it can display the operating status of the system in real time and give prompts in the form of menus . With the friendly HMI , users can easily query or set relevant information .

Adopting microprocessor technology and high intelligent design makes the data transmission fast and reliable and ensures the timeliness and correctness of data processing. With the anti-interference measures taken in both software and hardware, the entire system greatly reduces false alarms, thus improving the system stability.

It not only makes the project wiring greatly simplified, but also easy for wire threading and repairing, thus reducing maintenance cost of the project.

The controller has a built-in high-capacity memory, which can save historical data for a long time for querying at any time.

Gas type | Standard range (ppm) | Optional range (ppm) | Resolution (ppm) |

Chlorine (CL2) | 0-20 | 10,100 | 0.1 |

Carbon monoxide (CO) | 0-200 | 500,2000 | 1 |

Hydrogen sulfide (H2S) | 0-100 | 500,2000 | 0.1 |

Oxygen (O2) | 0-25%VOL | 0-30%VOL | 0.1%VOL |

Ammonia (NH3) | 0-100 | 100,1000 | 0.1 |

Ozone (O3) | 0-5/50 | 10,100 | 0.1 |

Hydrogen cyanide (HCN) | 0-100 | 50,200 | 0.1 |

Hydrogen chloride (HCI) | 0-100 | 100 | 0.1 |

Sulfur dioxide (SO2) | 0-100 | 100,1000 | 0.1 |

Hydrogen fluoride (HF) | 0-10 | 5,50 | 0.1 |

Combustible gas | 0-100%LEL | 0-100%LEL | 0.1%LEL |