Source:本站Date:2025-11-03

Inside high-heat-generating"big hearts"such as data centers and energy storage power stations,liquid cooling technology is becoming the absolute main force for heat dissipation.In this precise system,there is a key component that acts like a"heat transfer station",and its condition directly determines the efficiency and safety of the entire system-it is the plate heat exchanger.

Imagine that the liquid cooling system is filled with expensive,high-purity coolant flowing inside,which comes into direct contact with"delicate"chips such as the CPU and GPU and must remain absolutely clean.While external cooling towers or urban tap water,although low in cost,are bound to contain impurities,minerals and microorganisms.

How can the internal liquid transfer heat to the external liquid without allowing them to"mix together"?

At this point,it's the turn of the plate heat exchanger to make a brilliant appearance!

Plate heat exchangers are composed of a large number of thin plates made of stainless steel and other metals,with complex corrugated flow channels engraved on the plates.Cold and hot liquids flow in opposite directions in the adjacent plate channels.Heat can easily pass through the thin plates and be transferred from the hot side to the cold side.

Its core mission:isolation and heat transfer

Primary side(internal circulation):It flows with clean coolant inside and is responsible for removing the heat from the equipment.

Secondary side(external circulation):It flows with external cooling water,which is responsible for ultimately removing the heat.

The plate heat exchanger acts like a dedicated"goalkeeper",allowing the two liquids to only undergo"heat transfer through the air",physically completely isolated,thereby perfectly protecting the internal precision equipment and the clean liquid cooling circuit.

The four major advantages of plate heat exchangers

High efficiency and compact:The corrugated design generates turbulence,achieving extremely high heat transfer efficiency while maintaining a very small volume,making it highly suitable for scenarios with limited space.

Safety isolation:Preventing external dirty water from contaminating the internal system is the cornerstone of system reliability.

Precise temperature control:By adjusting the external water volume,the temperature of the coolant supplied to the equipment can be precisely controlled.

Easy maintenance:It can be easily opened for cleaning and maintenance.

If the plate heat exchanger is the"goalkeeper",then cleanliness is the bottom line that this goalkeeper must adhere to.Any tiny oil stain,metal shavings or particles could be an"invisible bomb"within the system,causing:

Decreased heat exchange efficiency:Dirt acts like a"cotton-padded jacket",enveloping the plates and hindering heat transfer,causing the equipment temperature to rise.

Flow channel blockage:Accumulation of particulate matter increases water flow resistance,raises the load on the water pump,and may even cause complete blockage.

Corrosion and leakage:Contaminants can accelerate system corrosion,eventually leading to leakage and causing disastrous consequences.

Therefore,cleanliness testing must run through the entire"life"of the plate heat exchanger.

A comprehensive physical examination of new equipment before it is put into use

A brand-new heat exchanger may carry"primary contamination"such as processing oil stains and metal shavings when it leaves the factory.Before accessing the system,one must go through a strict"purification ceremony".

Scientific Rinsing and Data Speak:

Build an independent circulation loop and use high-flow deionized water for"violent flushing".

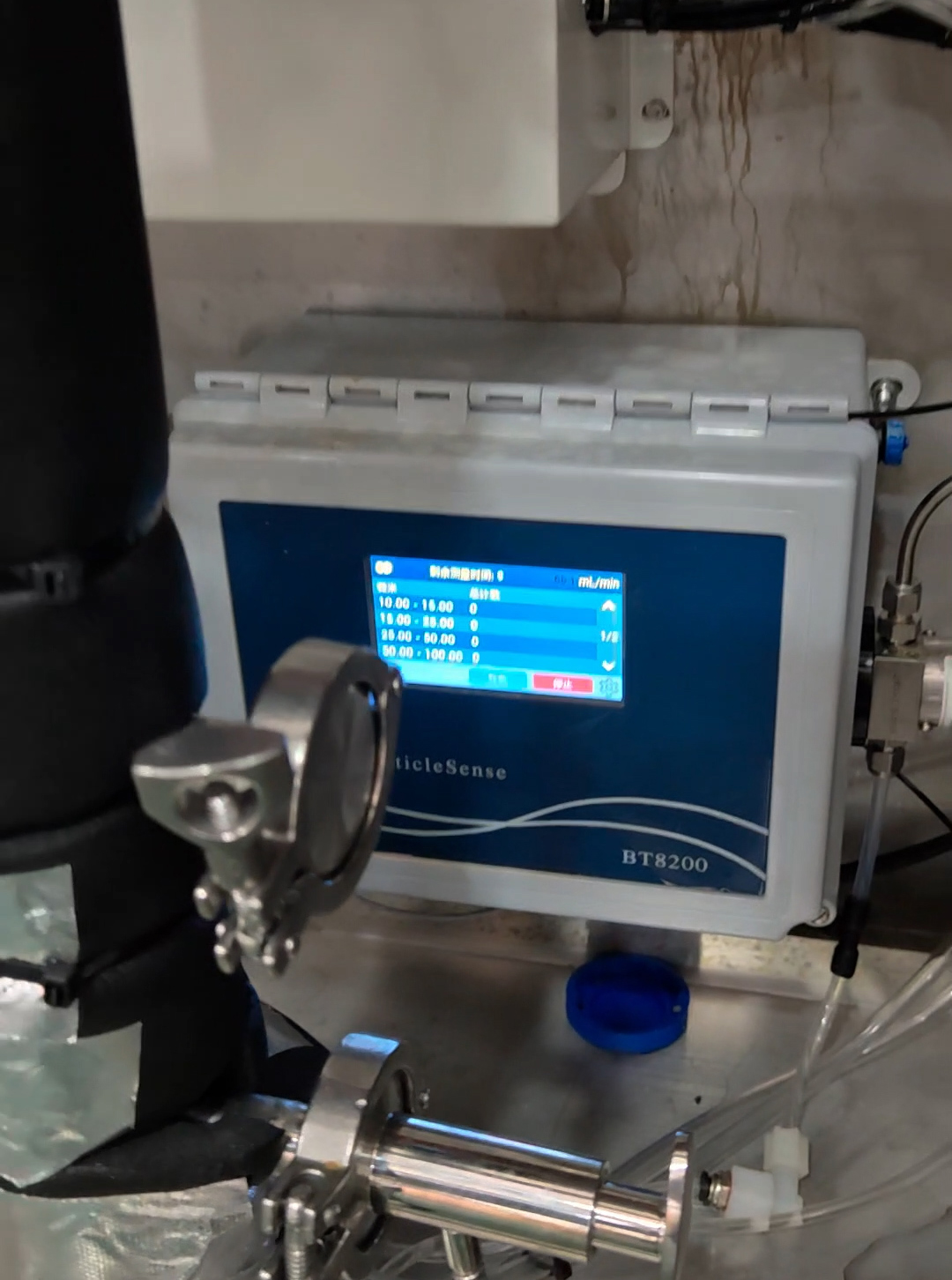

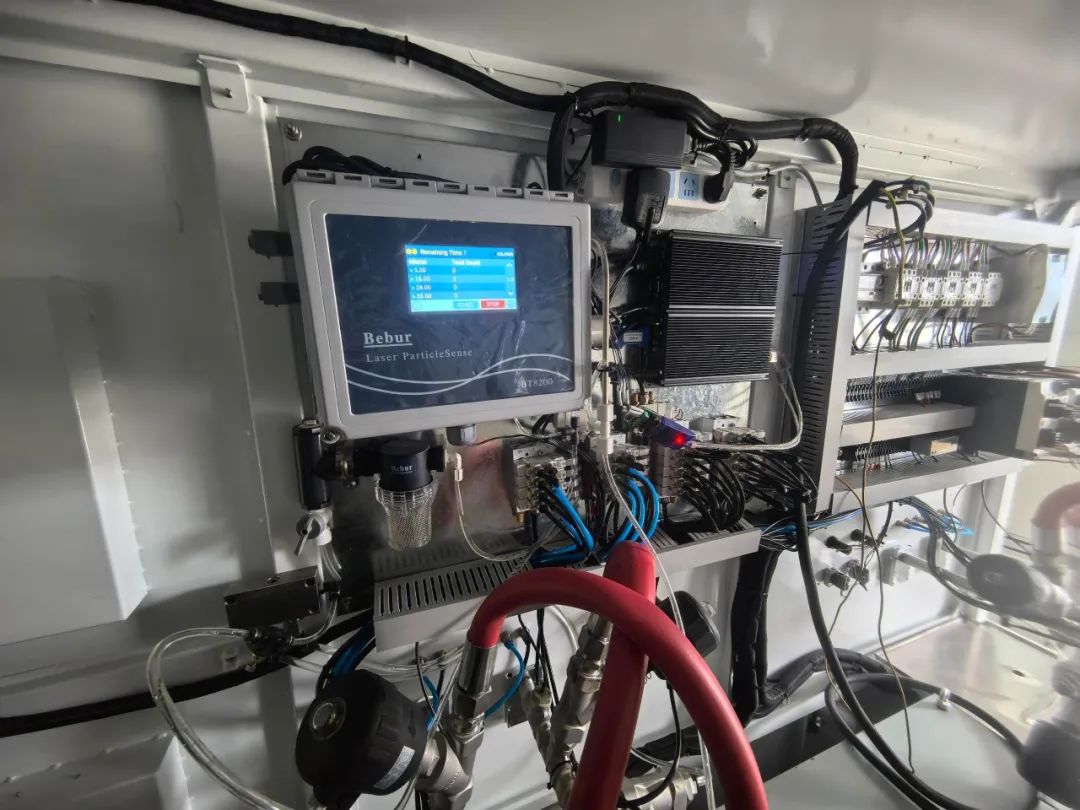

At the exit,a liquid particle counter is used for real-time monitoring.Only when the number of particles stably drops below the standard(such as the ISO cleanliness grade)can it be considered qualified.

The membrane filtration sampling method can also be adopted.After filtering the water sample,it is weighed and observed under a microscope to quantify the degree of cleanliness.

2."Regular physical examinations"and health care during operation

Even if it is very clean at the beginning,during long-term operation,the secondary side is prone to scale formation and the growth of bacteria and algae.It is necessary to monitor their"health indicators"regularly.

Performance monitoring(indirect judgment)

Taking body temperature:Under a fixed flow rate,if the temperature difference between the inlet and outlet becomes smaller,it indicates that it is"feverish"and the heat transfer efficiency has declined.

Blood pressure measurement:If the pressure drop passing through it increases,it indicates that the blood vessel(flow channel)may be blocked.

Direct inspection and maintenance

Regular"intestinal cleansing":Depending on the operation status,disassemble it regularly and give it a thorough"bath"with a brush,high-pressure water gun or chemical cleaning agent.

Water quality testing:Regularly test the cooling water on the secondary side to monitor its hardness,pH value,conductivity,etc.,to prevent scaling and corrosion from the source.

In today's pursuit of high computing power and high density,the significance of liquid cooling systems is self-evident.The plate heat exchanger,as its core heat exchange component,and cleanliness,as its lifeline,together form a solid guarantee for the stable operation of the system.

Suggestions for operation and maintenance engineers

Establish a strict cleanliness control system,from the"first line of defense"of new equipment acceptance to regular monitoring and maintenance during operation,to form a closed-loop management.Never lose the big picture for small gains.Let a tiny contaminant ruin the entire expensive liquid cooling system.

2025-11-20

2025-11-20

2025-11-20

2025-11-03

2025-11-03