Source:本站Date:2025-11-20

Behind the speeding electric vehicles and the roaring data centers,there is a key technology that quietly supports the stable operation of these high-heat devices-liquid cooling plates.

However,few people know that even advanced liquid cooling plates can fail due to a micron-sized metal shavings or a dust particle that is invisible to the naked eye.

The liquid particle counter,the"microscope"of the microscopic world,is precisely the ultimate guardian of the cleanliness of the liquid-cooled plate.

The interior of the liquid cooling plate is densely covered with micro-channels thinner than a human hair(about 0.1 to 1 millimeter in width),which transport the coolant like"blood vessels".However,once particulate pollutants are mixed in,the consequences would be unimaginable:

Blockage crisis:If there are too many micron-sized particles,they may directly block the micro-flow channels,leading to local overheating.

Wear down the circulating pump:Sharp particles will wear down the pump body like"sandpaper",shortening the system's lifespan.

Accelerated corrosion:Metal debris undergoes an electrochemical reaction with the coolant,causing perforation and leakage in the flow channel.

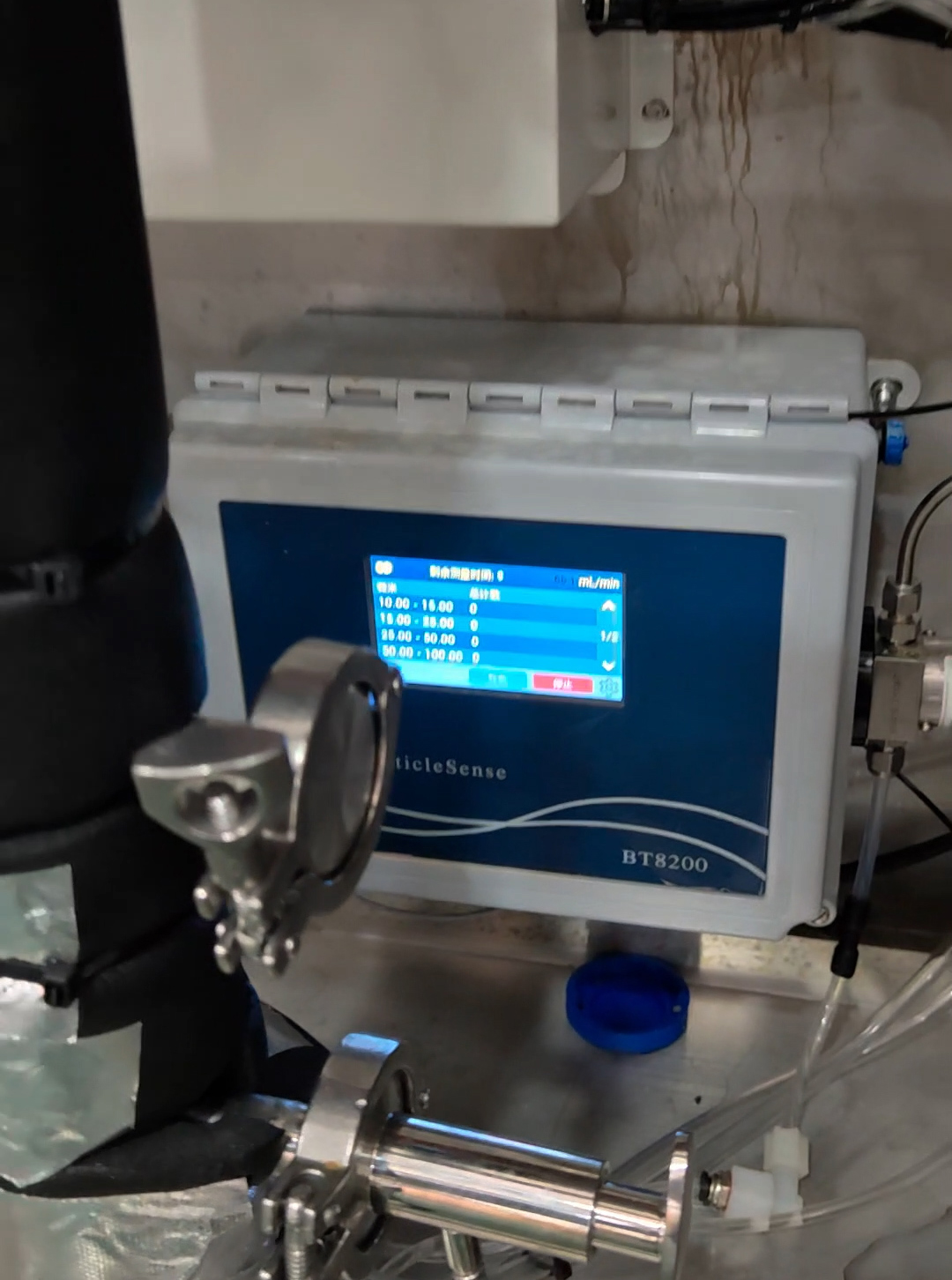

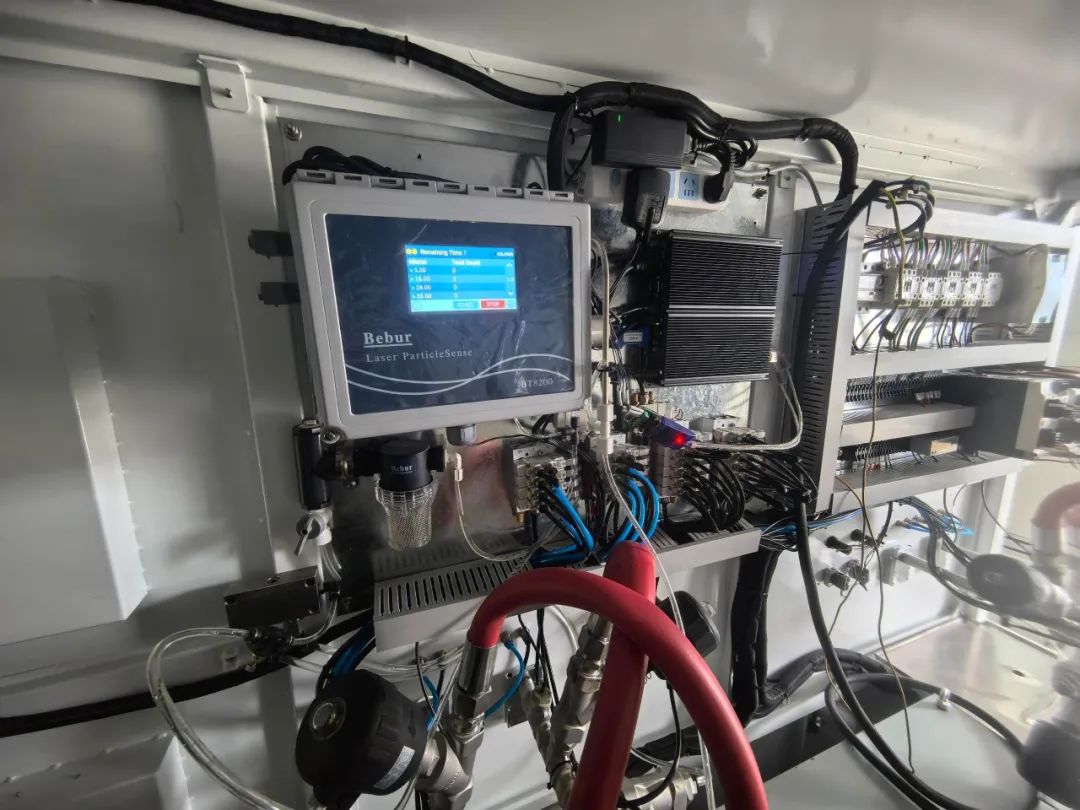

The core technology of the BT8200 liquid particle counter is the light obscuration method

Laser penetration:The liquid to be tested flows through a transparent detection cell,and a high-precision laser beam irradiates vertically.

Shadow capture:When particles pass through,they block the light,generating an instantaneous shadow signal.

Intelligent analysis:The sensor converts the particle size based on the shadow area,and the software counts the number of particles of different sizes in real time.

Detection range:Can identify particles ranging from 2 to 750 microns,covering common pollutants.

Channel display:8 particle size channels,customizable particle size detection range(such as 2-5 microns;5-15 microns;15-30 microns;30-50 microns;greater than 50 microns,etc.);

Rapid analysis:Second-level response,capable of quickly detecting the quantity and size of particles in liquids.

Residue detection:After ultrasonic cleaning,use a particle counter to randomly inspect the cleaning solution to ensure that metal shavings and welding slag are thoroughly removed and the cleanliness meets the standards.

Real-time monitoring:The data center detects the concentration of coolant particles in real time to prevent blockage.

Today,as liquid cooling technology advances towards innovation,liquid particle counters have been upgraded from"quality inspection tools"to"system health managers".It reveals the crises of the microscopic world with data and defends the reliability of macroscopic equipment with technology.As an engineer put it,"Every particle detected is a victory over a potential fault."

2025-11-20

2025-11-20

2025-11-20

2025-11-03

2025-11-03