Source:本站Date:2025-11-20

The cold plate liquid cooling system is composed of a secondary side cooling system,a primary side cooling system,a monitoring system,etc.A system that indirectly transfers the heat of components to the cooling medium enclosed in the circulation pipeline through cold plates,and ultimately discharges the heat of the equipment to the outside through heat exchange and transfer in one or more cooling circuits.

The secondary side cooling system is composed of secondary side cooling medium,cold plate,liquid quick connector,manifold,secondary side pipeline,cooling capacity distribution unit,etc.The primary side cooling system is composed of primary side cooling medium,primary side pipelines,outdoor cold source equipment and supporting equipment,etc.

In cold plate liquid cooling systems,the detection of particle cleanliness is of vital importance,as tiny particle contaminants can clog microchannels(especially in cold plates),wear out the bearings and seals of pumps,reduce heat exchange efficiency,and even cause system failures.

This article mainly introduces the components that need to undergo particle cleanliness testing in the cold plate liquid cooling system.

Reason:This is one of the key components.The microchannels inside the cold plate(especially those used for cooling the CPU/GPU)are very small in diameter(usually only a few tenths of a millimeter).Even very tiny particles(tens of micrometers)can clog these channels,causing local overheating and component failure.

Inspection points:After manufacturing is completed(after welding,brazing,and machining),before assembly,and after the entire system is cleaned.

The reason is that whether it is a water-cooled liquid-water heat exchanger or a water-cooled liquid-air heat exchanger(radiator),the internal flow channels are also relatively narrow(especially for plate heat exchangers).Particles will deposit on the flow channels or fins,reducing heat exchange efficiency and increasing flow resistance.

Inspection points:After manufacturing is completed,before assembly,and after the entire system is cleaned.

Reasons:including quick connectors,flanges,threaded connectors,etc.The grooves,sealing ring installation grooves,threads and other parts inside it are prone to retain processing debris or particles brought in during assembly.These particles will directly enter the main circulation under the scouring of the fluid.

Inspection points:After manufacturing/machining and before assembly(especially in the sealing surface area).

Reason:The inner walls of long straight pipes may retain contaminants from the manufacturing process(such as pipe bending,cutting)or storage.Although large pipe diameters are relatively less prone to clogging,particles will continuously contaminate the fluid and wear out other components.

Inspection points:After manufacturing/cutting/bending the pipe and before assembly(with particular attention to burrs on the cutting end face and internal cleaning).

The reason is that after all components have been cleaned and assembled,flushing the entire circulation loop and testing the particle concentration of the flushing solution is the final step to confirm whether the final cleanliness of the system meets the standards.This can detect contaminants introduced during the assembly process as well as possible"dead zone"residues.

Detection point:After the system assembly is completed and it has been flushed through the prescribed process,and before the working fluid is added.

All components in the cold plate liquid cooling system that come into direct contact with the coolant should be considered for particle cleanliness testing during their manufacturing process and after final assembly into the system,especially those with narrow flow channels,precision moving parts or those prone to contaminant deposition(cold plates,heat exchangers,distributors and collectors,UQD quick couplings).The final flushing fluid cleanliness detection at the system level is the last crucial checkpoint to ensure the reliable operation of the system.Strict cleanliness control is the foundation for ensuring the high performance,long service life and reliability of the liquid cooling system.

Particle counting is a quantitative and highly precise detection method used to determine the size distribution and concentration of solid particles in liquid samples or contaminants extracted from component surfaces.It is a core technology for evaluating the cleanliness of liquid cooling systems.

The working principle of the particle counting method is the light blockage method,which allows the liquid sample to be tested to flow through a very narrow transparent channel illuminated by a light beam.When particles in the liquid flow through,they block the light,causing the intensity of the light received by the sensor to instantly weaken.This change in light intensity is captured by the photoelectric sensor and converted into an electrical pulse signal.The amplitude of the pulse is directly proportional to the projected area of the particles(i.e.,the particle size).The instrument converts the pulse amplitude into the equivalent diameter of the particles(usually based on the diameter of the standard sphere)through calibration.Each pulse signal is counted as one particle.

The particle counting method has the advantages of fast detection speed,high precision,and the ability to simultaneously obtain the number of particles in multiple size channels.It is currently the mainstream method,but its disadvantage is that it cannot distinguish the material and shape of the particles.

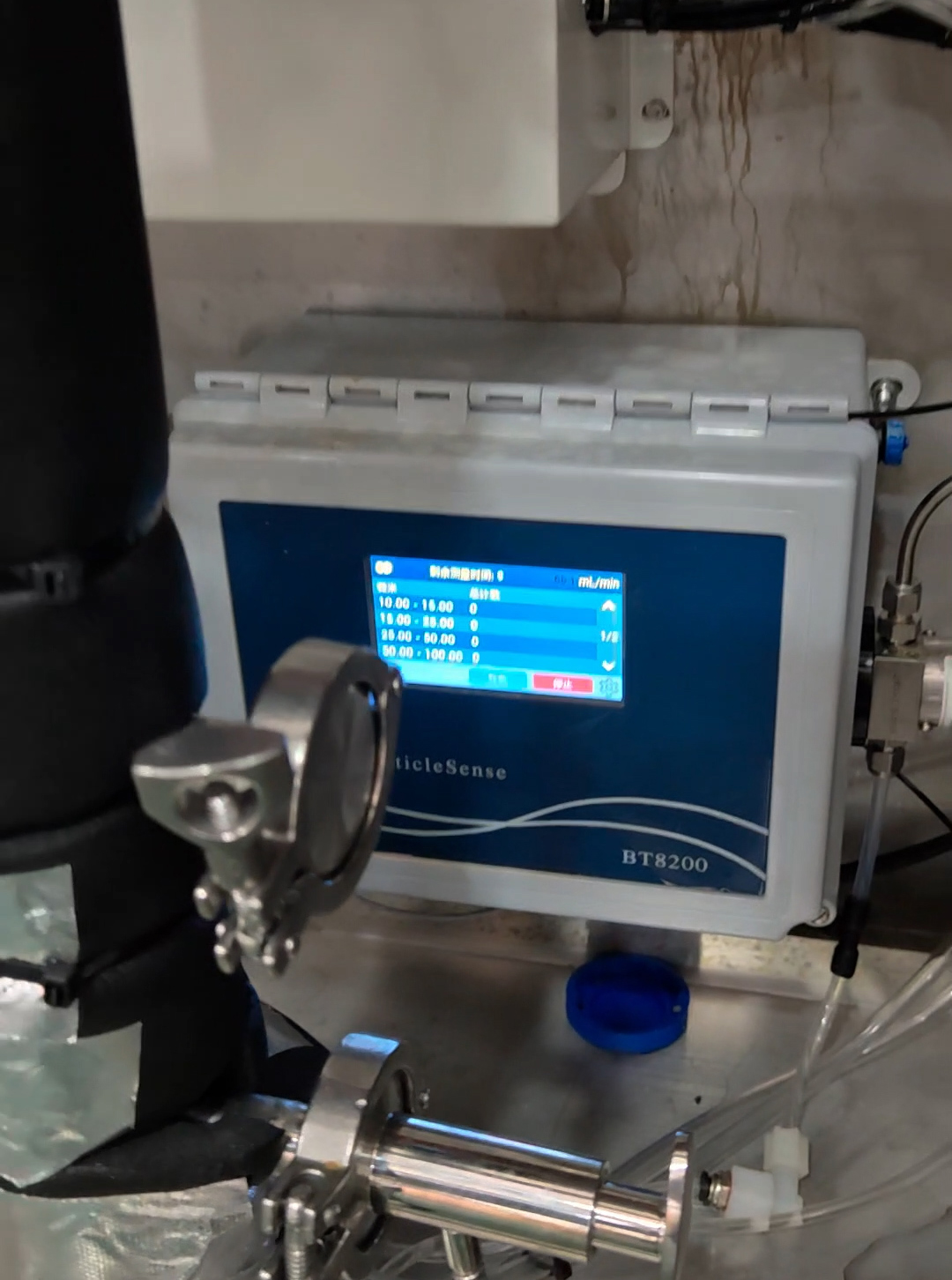

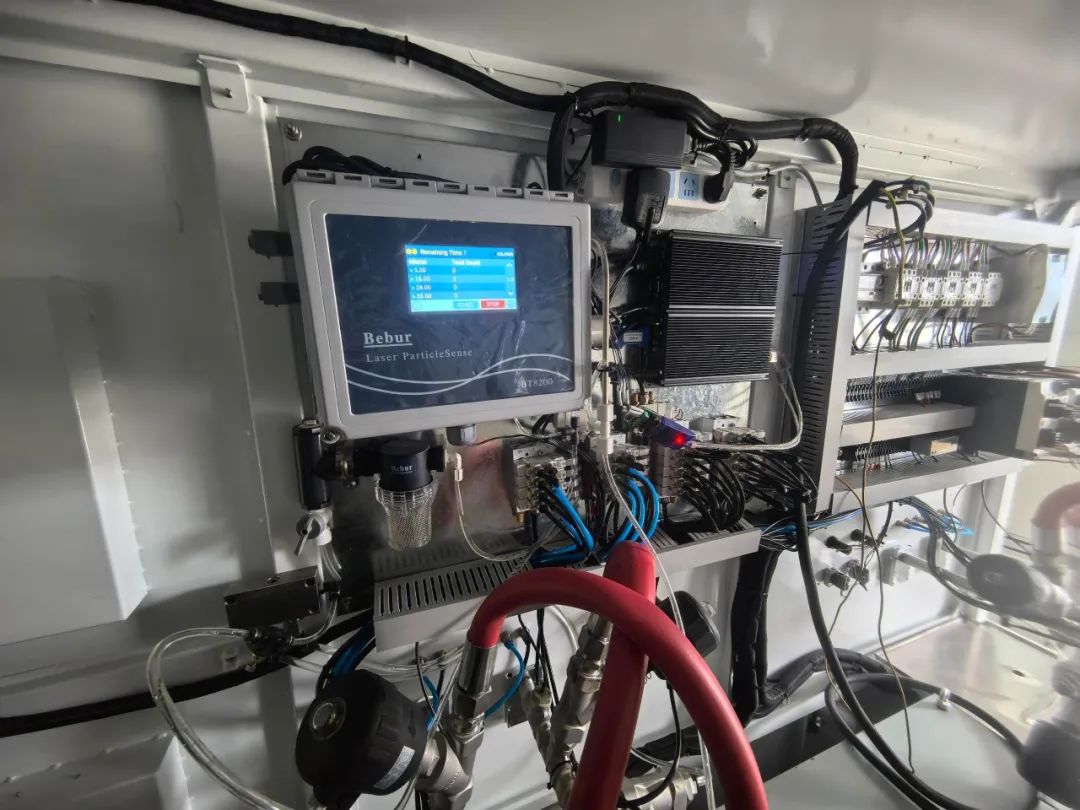

The BT8200 liquid particle counter from Babel uses the principle of light blockage for particle detection.It can simultaneously monitor the particle size and quantity in 8 channels.The device is reliable in performance and easy to use,meeting the diverse application needs of users.It is widely used in liquid cooling and heat dissipation,hydraulic systems,parts cleaning,casting machinery,pharmaceuticals,electronics and other industries.

For cold plate liquid cooling systems,the particle counting method is a key quality control measure for evaluating their reliability and lifespan.It precisely quantifies pollutant levels through principles such as the light blocking method,providing indisputable data basis for design,manufacturing and maintenance.Strictly controlling particle contamination is of Paramount importance for ensuring the efficient and stable operation of liquid cooling systems,especially those involving microchannel cold plates.

2025-11-20

2025-11-20

2025-11-20

2025-11-03

2025-11-03