Source:本站Date:2025-11-03

In the era of explosive computing power,liquid cooling technology has become the absolute leading role in heat dissipation for high-density data centers.When we talk about liquid cooling,we always focus on the coolant and the cold plate.However,there is one core component that is crucial but often overlooked-it is the Manifold.

If coolant is the"blood"of a data center,then Manifold is the precisely designed"heart"and"vascular network".Its performance and cleanliness directly determine the survival of the entire liquid cooling system.

In simple terms,Manifold is a multi-path connector,but it is far more than just a connector.Its core mission is:precise allocation and efficient aggregation.

Precise"flow scheduler":In a server filled with Gpus and cpus,Manifold is responsible for evenly distributing the total coolant flow from the water pump to the cold plates of each heat-generating element.Imagine if there were a"diversion",with some chips"drinking their fill"of coolant while others"thirsty",the inevitable result would be local overheating,a sudden drop in performance,or even system crashes.An excellent Manifold ensures that all key components are cooled equally and thoroughly through a precise flow channel design.

The"integrated hub"of the system:It replaces the spider-web-like complex pipes and joints with an integrated design.This not only makes the system structure more compact,but also significantly reduces potential leakage points,enhancing the overall reliability and maintainability.In cabinet-level liquid cooling,the core of that huge coolant distribution unit(CDU)is often a highly complex Manifold.

If design determines the"intelligence quotient"of Manifold,then cleanliness determines its"lifespan".Here,"spotless"is not an adjective but the most fundamental requirement for survival.Any tiny pollutant may trigger a chain reaction disaster.

The Invisible Enemy:The Three Major Hazards of Pollutants

The number one killer:Particulate matter clogging chips

The flow channels inside the cold plate are as thin as hair.A tiny metal chip or welding slag is enough to form a"blood clot",completely blocking the flow path.The consequences are immediate:the corresponding chip area will heat up sharply and eventually burn out due to a"high fever".

Chronic poison:Oils and biological growth

The grease or fingerprints left over from the processing are a"feast"for microorganisms(bacteria,algae).They will multiply within the system,forming biofilms that not only block the flow channels but also corrode metals with their metabolic products,causing double damage.

Invisible bomb:Ion Contamination and Corrosion

Residual cleaning agents or flux can introduce ionic contamination and increase the conductivity of the coolant.In an electrified environment,this can form an"original battery"between different metal materials,causing electrochemical corrosion and eventually leading to component perforation,coolant leakage,and even short circuits.

How to achieve"surgical grade"cleaning?A micro-war that runs through the entire process

Controlling the cleanliness of Manifold is a systematic project that runs through the entire process of design,manufacturing and assembly.

Design source:From the design of the flow channel,dead corners and complex structures that are difficult to clean are avoided,leaving contaminants"nowhere to hide".

Precision cleaning:Use high-purity deionized water for powerful cleaning.

Drying and sealing:Immediately after cleaning,thoroughly dry with clean hot air or nitrogen,and immediately put"sterile masks"(sealing covers)on all interfaces to isolate external contamination.

Cleanroom assembly:The final assembly must be carried out in a cleanroom,where operators are fully equipped(dust-free suits,gloves,masks),just like performing a precise surgical operation.

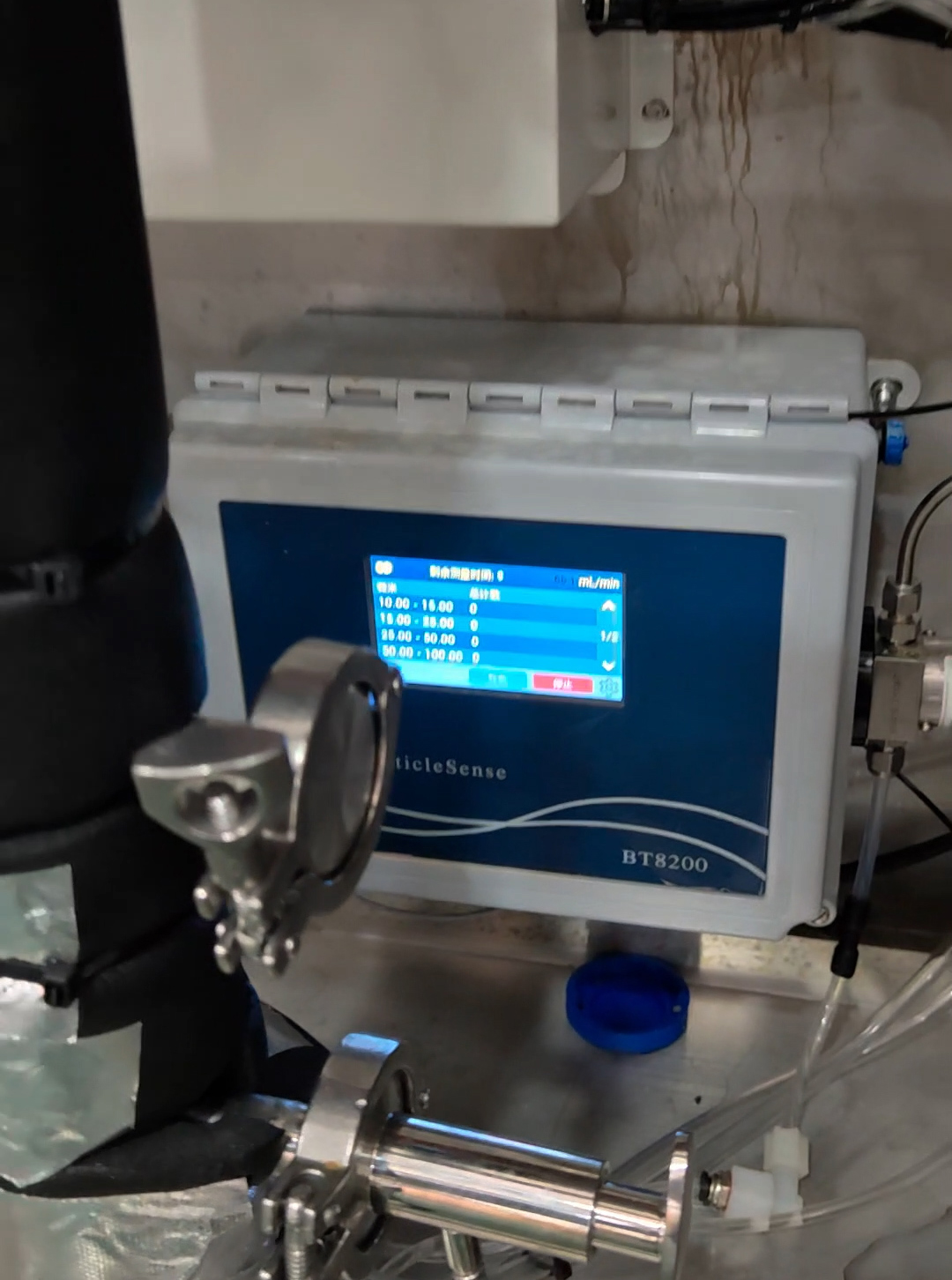

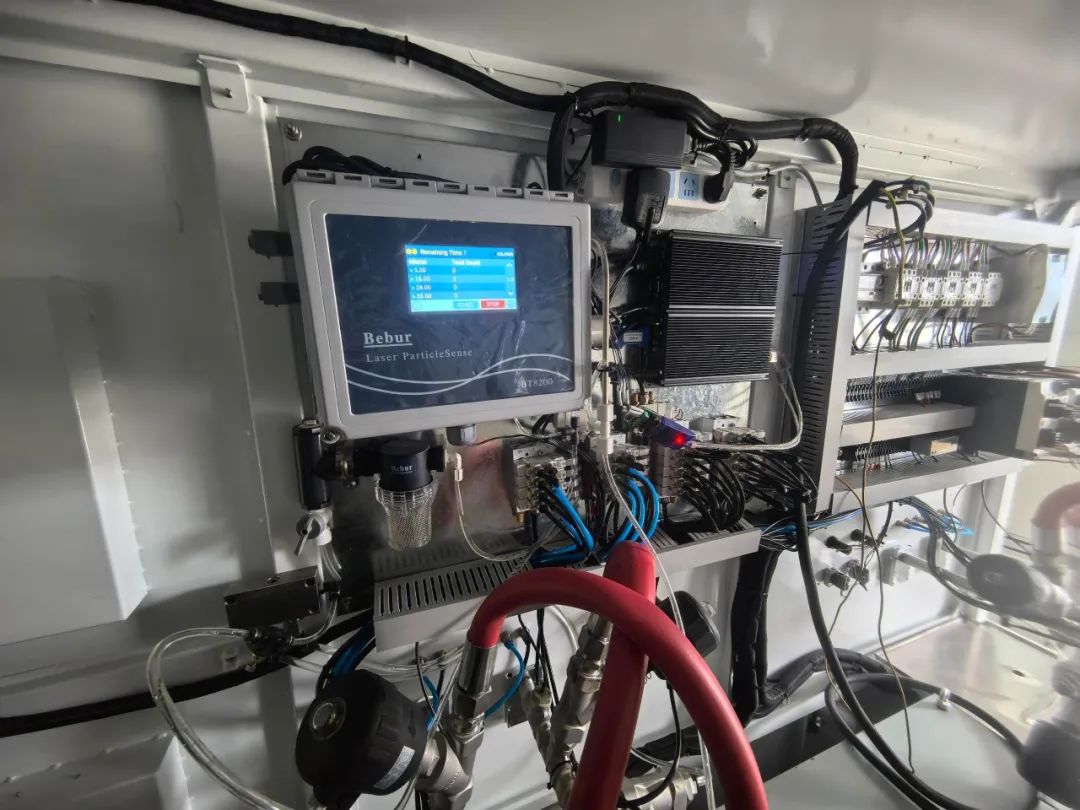

Authoritative"physical examination":In accordance with international standards such as ISO 16232,particle counting and ion contamination degree detection are carried out on the cleaned liquid.Data speaks for itself to ensure that each Manifold is"healthy and up to standard".A liquid particle counter and a conductivity meter are needed here.

Details determine success or failure,and purity leads to a distant future.Today,in the pursuit of ultimate computing power and energy efficiency,liquid cooling technology is moving from being"optional"to"essential".And Manifold,this unsung"flow commander",its design and cleanliness level are precisely the key yardstick for measuring the technical depth and professionalism of a liquid cooling supplier.

2025-11-20

2025-11-20

2025-11-20

2025-11-03

2025-11-03