Source:本站Date:2025-11-20

The application of liquid particle counters in liquid cooling systems is particularly crucial,especially in scenarios with high power density and precise heat dissipation requirements.The liquid cooling system directly or indirectly removes heat through liquid circulation,but particulate contaminants in the liquid may cause blockage,corrosion,reduced heat dissipation efficiency,and even system failure.This article introduces the specific applications and core values of liquid particle counters in liquid cooling systems.

Scene features

Data center servers use liquid cooling(immersion or cold plate type)instead of traditional air cooling.The coolant(such as deionized water or electronic fluorinated liquid)directly contacts the heat-generating components,achieving high heat dissipation efficiency.However,it has strict requirements for the cleanliness of the liquid.

Particle contamination problem

Micron-sized particles can clog microchannel cold plates or pump valves,leading to a decrease in flow rate and local overheating.

Conductive particles may cause a short circuit in the circuit.

Biological contaminants may breed blockages or corrode pipelines.

The function of a liquid particle counter:

Real-time monitoring:Online detection of particle concentration and size distribution in the coolant(such as≥2µm,≥5µm,≥15µm)to ensure compliance with relevant cleanliness grades.

Preventive maintenance:When the particle concentration exceeds the standard,an alarm is triggered,and the filtration system is linked to automatically purify,avoiding the risk of shutdown.

Advantages

Enhance the stability of heat dissipation and reduce the risk of downtime in data centers caused by overheating.

Scene features

High-power semiconductor devices(such as IGBTs)are precisely temperature-controlled through liquid cooling plates.The coolant(deionized water,ethylene glycol)flows through sub-millimeter channels,and even tiny particles can cause blockages.

Particle contamination problem

Ion pollution:If deionized water contains silicon or metal particles,it may reduce insulation and cause electrochemical corrosion.

Fiber contamination:Fibers that have fallen off from the filter element or sealing material get entangled in the flow channel.

The function of a liquid particle counter:

Process control:Test the cleanliness of the coolant(deionized water,etc.)before filling to ensure there is no risk of clogging.

Long-term health management:Monitor the trend of particle concentration changes,predict the lifespan of filter elements or the risk of system leakage.

Advantages

Ensure the heat dissipation performance of high-power devices to prevent overheating and damage.

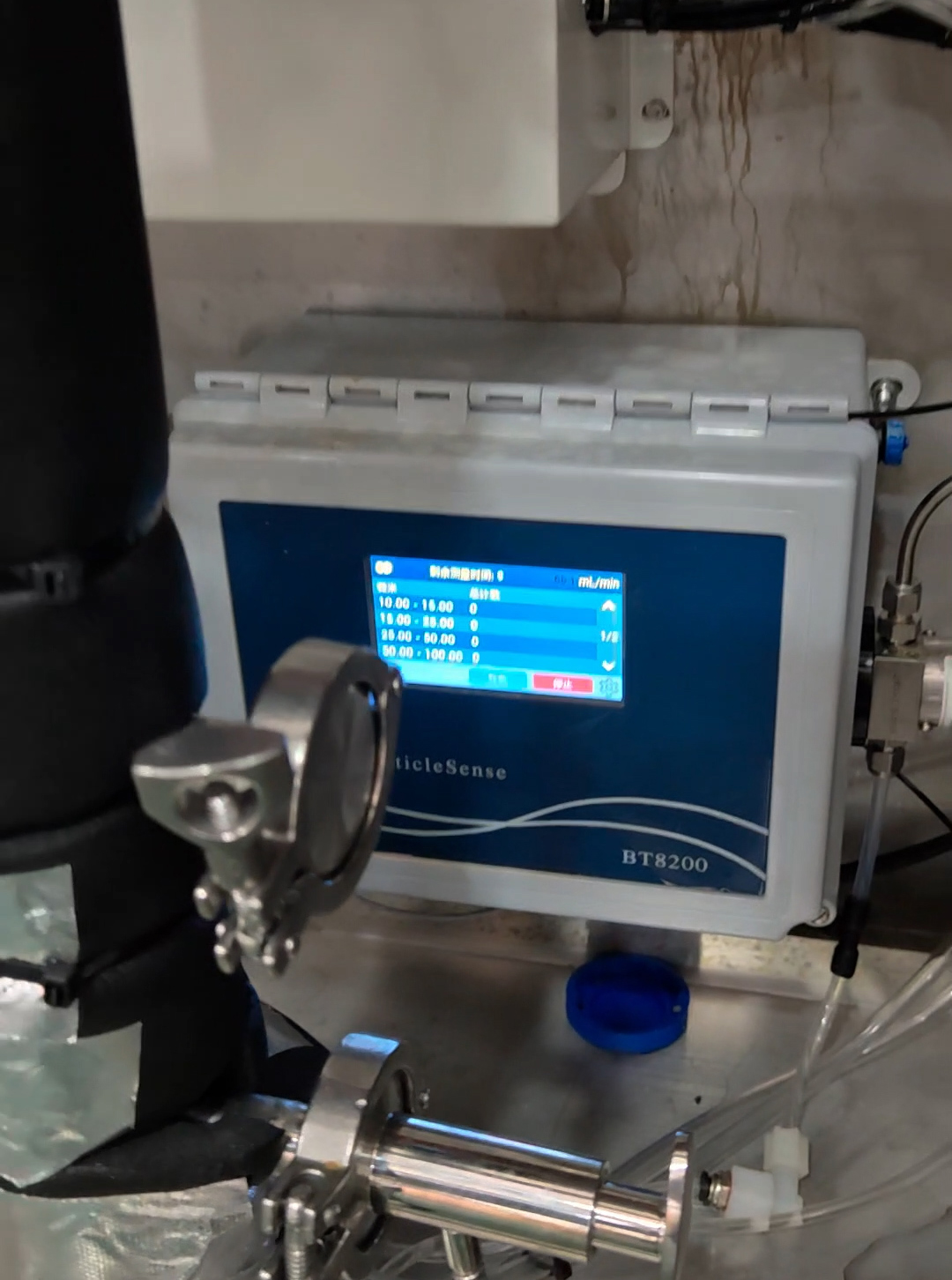

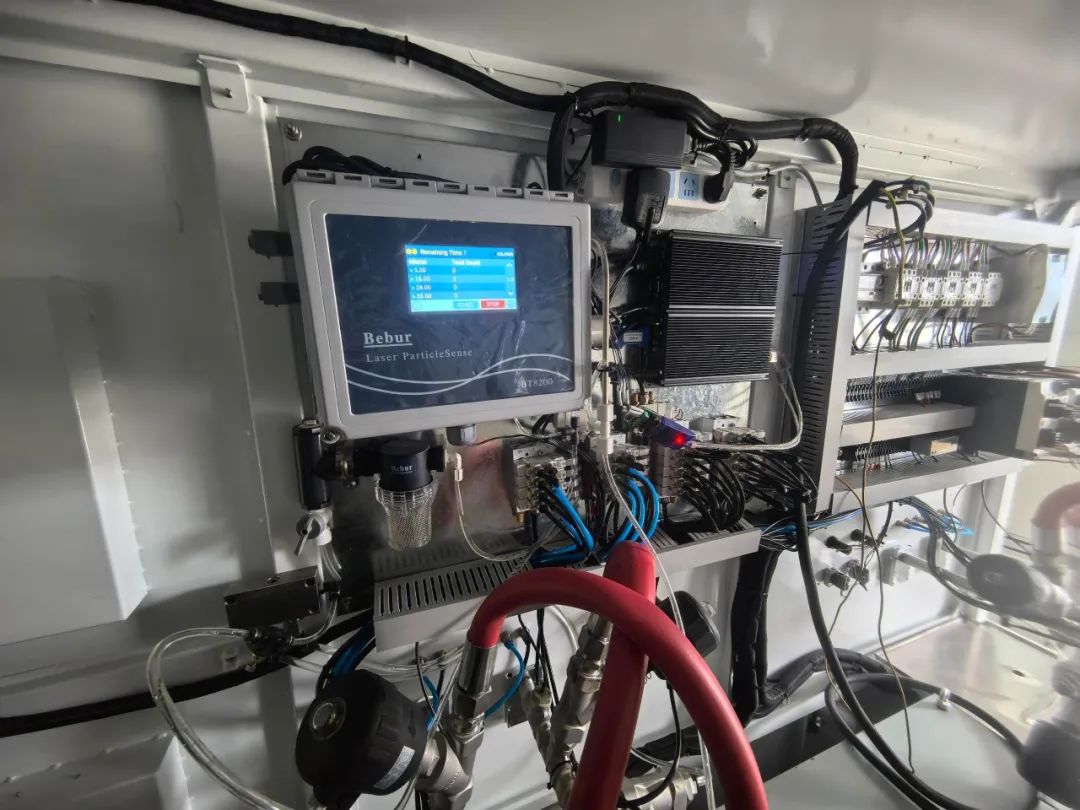

The Bebur BT8200 liquid particle counter can simultaneously monitor the particle size and corresponding quantity of 8 channels.It adopts the principle of light blockage and can monitor particles with a particle size range of 2-750μm.

The performance of the liquid cooling system is directly related to the cleanliness of the coolant.The liquid particle counter,through real-time monitoring,early warning and closed-loop control,becomes the"gatekeeper"to ensure the reliability of the liquid cooling system.

2025-11-20

2025-11-20

2025-11-20

2025-11-03

2025-11-03